-

Phone:

Phone: -

Email:

Email:

Jan . 25, 2025 04:12

Back to list

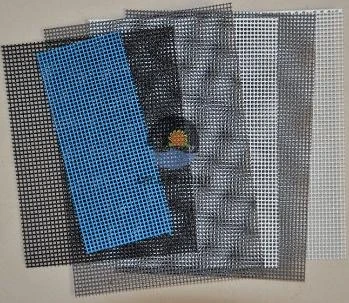

double loop rebar tie wire

Steel rebar tie wire is an indispensable component in the construction industry, revered for its critical role in reinforcing and stabilizing concrete structures. The application of this understated yet pivotal tool goes beyond simple ties, intertwining with the very foundation of our built environment.

The advancements in automation have introduced innovative tie wire machines, which enhance speed and consistency in larger projects. However, human expertise continues to be indispensable, particularly in assessing situations where machines may not adapt well to unique structural nuances. Skilled workers' experience in choosing the right tying patterns cannot be overlooked, as they ensure customized solutions that uphold the highest standards of safety and efficacy. Furthermore, sustainability is increasingly at the forefront of construction materials. Environmentally conscious manufacturers are producing rebar tie wire with recycled materials, reducing waste and lowering the carbon footprint. This environmentally sustainable approach aligns with global trends towards green building practices, adding another layer of authority and trustworthiness to the industry. From the perspective of purchasing and supply, contractors are advised to select suppliers who mirror their commitment to quality and sustainability. Reputable suppliers provide not only high-grade materials but also value-added services like technical support and training, enhancing the overall competence of the construction teams. Whether employed in a towering skyscraper or a humble residential dwelling, rebar tie wire remains an unsung hero in construction, integral to ensuring buildings stand the test of time and elements. It embodies expertise and reliability, reinforcing not only concrete but also the confidence of engineers, builders, and occupants alike. With its crucial application and unwavering dependability, steel rebar tie wire exemplifies an engineering marvel that quietly, yet powerfully, supports the backbone of modern infrastructure.

The advancements in automation have introduced innovative tie wire machines, which enhance speed and consistency in larger projects. However, human expertise continues to be indispensable, particularly in assessing situations where machines may not adapt well to unique structural nuances. Skilled workers' experience in choosing the right tying patterns cannot be overlooked, as they ensure customized solutions that uphold the highest standards of safety and efficacy. Furthermore, sustainability is increasingly at the forefront of construction materials. Environmentally conscious manufacturers are producing rebar tie wire with recycled materials, reducing waste and lowering the carbon footprint. This environmentally sustainable approach aligns with global trends towards green building practices, adding another layer of authority and trustworthiness to the industry. From the perspective of purchasing and supply, contractors are advised to select suppliers who mirror their commitment to quality and sustainability. Reputable suppliers provide not only high-grade materials but also value-added services like technical support and training, enhancing the overall competence of the construction teams. Whether employed in a towering skyscraper or a humble residential dwelling, rebar tie wire remains an unsung hero in construction, integral to ensuring buildings stand the test of time and elements. It embodies expertise and reliability, reinforcing not only concrete but also the confidence of engineers, builders, and occupants alike. With its crucial application and unwavering dependability, steel rebar tie wire exemplifies an engineering marvel that quietly, yet powerfully, supports the backbone of modern infrastructure.

Next:

Latest news

-

Wire Mesh for Every Need: A Practical SolutionNewsJul.25,2025

-

Steel Fences: Durable, Secure, and Stylish OptionsNewsJul.25,2025

-

Roll Top Fencing: A Smart Solution for Safety and SecurityNewsJul.25,2025

-

Cattle Farm Fencing Solutions for Maximum SecurityNewsJul.25,2025

-

Affordable Iron Binding Wire SolutionsNewsJul.25,2025

-

Affordable Galvanized Wire SolutionsNewsJul.25,2025

-

Wire Hanger Recycling IdeasNewsJul.25,2025

Related PRODUCTS