-

Phone:

Phone: -

Email:

Email:

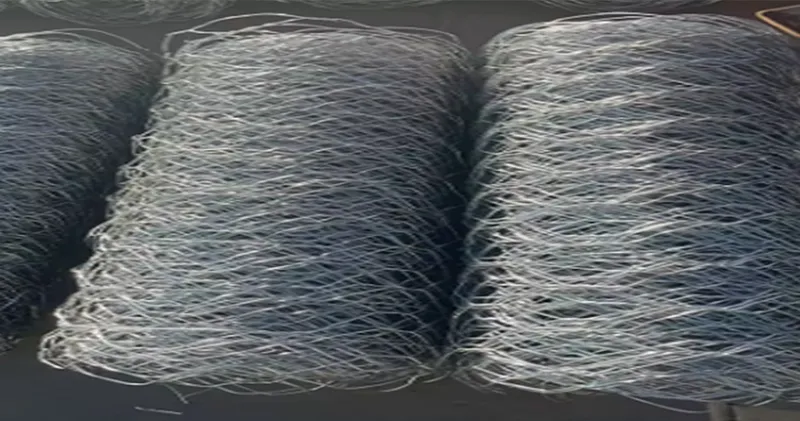

steel tie wire

Understanding Steel Tie Wire Applications and Benefits

Steel tie wire is a versatile and indispensable material within the construction and manufacturing industries. This strong, flexible wire is primarily used for tying reinforcement bars (rebar) together and securing various components in place during the construction process. Made from high-quality steel, tie wire offers several advantages that contribute to its widespread use in different projects, from residential buildings to large-scale industrial constructions.

Composition and Properties

Steel tie wire is typically made from low-carbon steel, allowing it to exhibit excellent tensile strength and flexibility. These properties enable construction workers to easily manipulate the wire into various shapes and knots without breaking or deforming. The wire is usually coated with a layer of corrosion-resistant material to enhance its durability and longevity, ensuring that it can withstand various environmental conditions.

Applications in Construction

One of the primary applications of steel tie wire is its use in rebar tying. In reinforced concrete structures, rebar provides the necessary tensile strength, while concrete offers compressive strength. To ensure the effectiveness of the structural integrity, these rebar pieces must be securely tied together using steel tie wire. This helps maintain the positioning of the rebar during concrete pouring, preventing movements that could lead to structural weaknesses.

In addition to tying rebar, steel tie wire is also used in the assembly of fence systems. Whether for residential, agricultural, or industrial purposes, this wire provides a reliable method for securing fence components. It is often used in conjunction with other fastening materials to create a robust and long-lasting fencing solution.

steel tie wire

Moreover, steel tie wire finds applications in various sectors, such as the automotive industry, where it is utilized for bundling components and securing parts during shipment

. In manufacturing, it is used to hold together products during assembly processes or to package items for transport.Environmental Benefits

One of the noteworthy advantages of steel tie wire is its recyclability. Made from steel, it can be easily recycled without losing quality, making it an environmentally friendly option in construction and manufacturing. This aspect is particularly important as industries increasingly focus on sustainable practices and reducing their carbon footprint.

Installation and Handling

The installation of steel tie wire is straightforward, which is another reason for its popularity in construction. It typically comes in coils or spool forms, making it easy to handle and apply. Workers use tools like wire cutters and pliers to cut and twist the wire, allowing them to create tight, secure knots. This ease of use not only speeds up the construction process but also reduces labor costs, as fewer tools and specialized skills are required.

Conclusion

Steel tie wire is a fundamental component in modern construction and manufacturing. Its strength, flexibility, and ease of use make it an ideal choice for ensuring the stability and safety of various structures. Additionally, its environmental benefits and recyclability align with contemporary sustainability goals, making it a responsible option for businesses. As the construction industry continues to evolve, steel tie wire will undoubtedly remain a critical material in building the foundations of our infrastructure. With its diverse applications and critical role in ensuring structural integrity, understanding the importance and functionality of steel tie wire is essential for anyone involved in construction, manufacturing, or related fields.

-

Wire Mesh for Every Need: A Practical SolutionNewsJul.25,2025

-

Steel Fences: Durable, Secure, and Stylish OptionsNewsJul.25,2025

-

Roll Top Fencing: A Smart Solution for Safety and SecurityNewsJul.25,2025

-

Cattle Farm Fencing Solutions for Maximum SecurityNewsJul.25,2025

-

Affordable Iron Binding Wire SolutionsNewsJul.25,2025

-

Affordable Galvanized Wire SolutionsNewsJul.25,2025

-

Wire Hanger Recycling IdeasNewsJul.25,2025