-

Phone:

Phone: -

Email:

Email:

tie metal wire

The Versatility of Tie Metal Wire Applications, Benefits, and Innovations

Tie metal wire, often referred to as binding or tying wire, is a crucial yet frequently overlooked material in various industries. This thin, flexible wire is made from different metals such as steel, aluminum, and copper, and its myriad uses make it an essential tool in construction, gardening, crafting, and numerous industrial applications.

Understanding Tie Metal Wire

Tie metal wire typically comes in a variety of gauges (thicknesses) and is available in several finishes, including galvanized and stainless steel. The choice of material and finish not only affects the strength and flexibility of the wire but also its resistance to corrosion and environmental factors. For instance, galvanized wire is coated with a layer of zinc, which protects it from rust, making it ideal for outdoor applications.

Applications in Construction

One of the most significant applications of tie metal wire is in the construction industry. Here, it is primarily used for tying rebar together to reinforce concrete structures. This application is crucial for ensuring the stability and durability of buildings, bridges, and other infrastructural elements. The flexibility of tie wire allows for easy manipulation, ensuring secure binding that can withstand substantial loads.

In addition to rebar tying, metal wire is used in scaffolding, where it serves as a temporary support structure. It helps secure planks and other materials, ensuring worker safety on construction sites. Moreover, tie wire is essential in creating cages for concrete pours, enabling precise shapes and structural integrity.

Gardening and Landscaping Uses

In gardening and landscaping, tie metal wire plays a vital role. It helps secure plants to supports, enabling vertical growth and providing stability against wind and other environmental factors. Gardeners commonly use it to tie up tomatoes and other climbing plants. The wire is also useful in constructing trellises, allowing for efficient space management and plant health through improved sunlight exposure.

tie metal wire

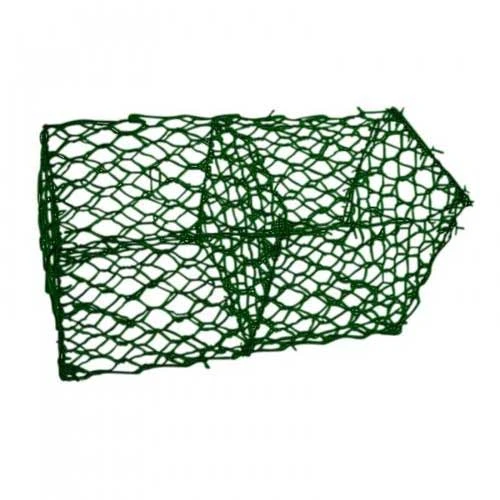

Furthermore, in landscaping projects, tie wire is often used to hold together various elements such as rocks and boulders in hardscaping scenarios. It can also be applied in creating wire frames for topiary designs or supporting floral arrangements, further exemplifying its flexibility.

Crafting and Art Applications

The crafting world has also embraced the use of tie metal wire. Its malleability lends itself well to various creative projects, from jewelry making to sculpture. Crafters can use tie wire to create intricate designs or durable frames for their artwork. The ability to sculpt and bend this material means it can take on countless forms, appealing to both amateur and professional artists alike.

In DIY projects, tie wire serves many purposes, whether it's to repair broken items, create custom holder baskets, or even make seasonal decorations. Its affordability and ease of use make it a staple in any crafter's toolkit.

Innovations and Sustainability

In recent years, innovations in metal wire production have focused on sustainability. Eco-friendly processes for galvanizing and recycling metal have emerged, meaning that consumers can choose products that are not only functional but also reduce environmental impact. Moreover, with the rise of circular economy principles, recycling and reusing metal tie wire have become more common, ensuring a longer lifecycle for this versatile material.

Conclusion

Tie metal wire is a remarkable tool that crosses the boundaries of various fields, from construction to crafting. Its unique properties, including flexibility, strength, and resistance to corrosion, make it indispensable in multiple applications. As industries continue to evolve, so too will the uses and innovations surrounding tie metal wire, ensuring its place as a fundamental material in our everyday lives. Whether you're a builder, gardener, or artist, having a spool of tie metal wire on hand can empower you to tackle projects with efficiency and creativity.

-

Wire Mesh for Every Need: A Practical SolutionNewsJul.25,2025

-

Steel Fences: Durable, Secure, and Stylish OptionsNewsJul.25,2025

-

Roll Top Fencing: A Smart Solution for Safety and SecurityNewsJul.25,2025

-

Cattle Farm Fencing Solutions for Maximum SecurityNewsJul.25,2025

-

Affordable Iron Binding Wire SolutionsNewsJul.25,2025

-

Affordable Galvanized Wire SolutionsNewsJul.25,2025

-

Wire Hanger Recycling IdeasNewsJul.25,2025