-

Phone:

Phone: -

Email:

Email:

Jan . 25, 2025 20:47

Back to list

tie metal wire

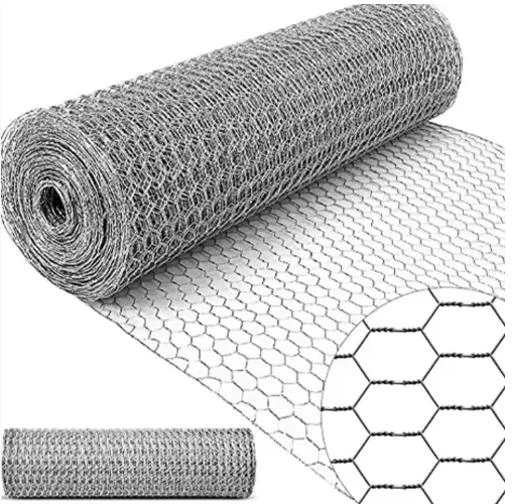

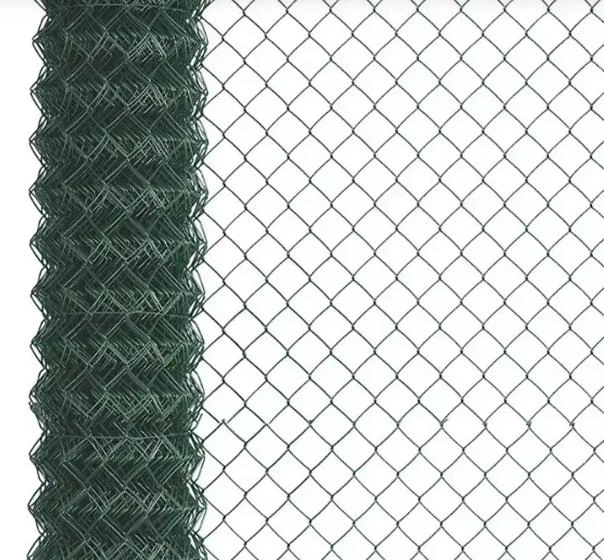

The art of tying metal wire is a craft that combines expertise, creativity, and practical application. Metal wire ties are used across multiple industries, including construction, art, and household projects. Understanding the nuances of this craft ensures not only the structural integrity of the projects it supports but also demonstrates a blend of human ingenuity and robust engineering.

For those breaking into the craft, workshops or tutorials can be immensely beneficial. These educational resources provide hands-on experience with expert guidance and are often led by professionals who have honed their skills over many years. They delve deep into the technical aspects and safety protocols, offering insights that are difficult to glean through online content or theoretical study alone. Furthermore, understanding the applications of metal wire tying outside of traditional industries can expand the skill sets of individuals seeking to innovate. In the tech world, for example, copper wire is used extensively in circuits and electronics due to its conductivity. Artists often use metal wire in sculpture not just for support, but as an aesthetic element that adds texture and form. This cross-disciplinary knowledge empowers individuals to think creatively about how metal wire can be integrated into their projects. Trustworthiness in handling metal wire products is often established through the adherence to industry standards and certifications. Manufacturers of metal wire are generally expected to follow rigorous production standards, ensuring that only the best quality materials reach consumers. Consumers can verify this by checking quality marks or certification labels, which indicate that the product has undergone extensive testing and is safe for use. In conclusion, mastering the craft of metal wire tying marries technical know-how with a thoughtful, safety-conscious approach. From selecting the right type of wire to executing precise knots, every step necessitates a level of expertise and care that can only be achieved through experience and a commitment to learning. As this essential skill finds diverse applications across multiple industries, those with expert knowledge of metal wire tying will always find that their skills are in demand, paving the way for an intriguing merging of practicality and creativity.

For those breaking into the craft, workshops or tutorials can be immensely beneficial. These educational resources provide hands-on experience with expert guidance and are often led by professionals who have honed their skills over many years. They delve deep into the technical aspects and safety protocols, offering insights that are difficult to glean through online content or theoretical study alone. Furthermore, understanding the applications of metal wire tying outside of traditional industries can expand the skill sets of individuals seeking to innovate. In the tech world, for example, copper wire is used extensively in circuits and electronics due to its conductivity. Artists often use metal wire in sculpture not just for support, but as an aesthetic element that adds texture and form. This cross-disciplinary knowledge empowers individuals to think creatively about how metal wire can be integrated into their projects. Trustworthiness in handling metal wire products is often established through the adherence to industry standards and certifications. Manufacturers of metal wire are generally expected to follow rigorous production standards, ensuring that only the best quality materials reach consumers. Consumers can verify this by checking quality marks or certification labels, which indicate that the product has undergone extensive testing and is safe for use. In conclusion, mastering the craft of metal wire tying marries technical know-how with a thoughtful, safety-conscious approach. From selecting the right type of wire to executing precise knots, every step necessitates a level of expertise and care that can only be achieved through experience and a commitment to learning. As this essential skill finds diverse applications across multiple industries, those with expert knowledge of metal wire tying will always find that their skills are in demand, paving the way for an intriguing merging of practicality and creativity.

Next:

Latest news

-

Wire Mesh for Every Need: A Practical SolutionNewsJul.25,2025

-

Steel Fences: Durable, Secure, and Stylish OptionsNewsJul.25,2025

-

Roll Top Fencing: A Smart Solution for Safety and SecurityNewsJul.25,2025

-

Cattle Farm Fencing Solutions for Maximum SecurityNewsJul.25,2025

-

Affordable Iron Binding Wire SolutionsNewsJul.25,2025

-

Affordable Galvanized Wire SolutionsNewsJul.25,2025

-

Wire Hanger Recycling IdeasNewsJul.25,2025

Related PRODUCTS