-

Phone:

Phone: -

Email:

Email:

Feb . 11, 2025 10:36

Back to list

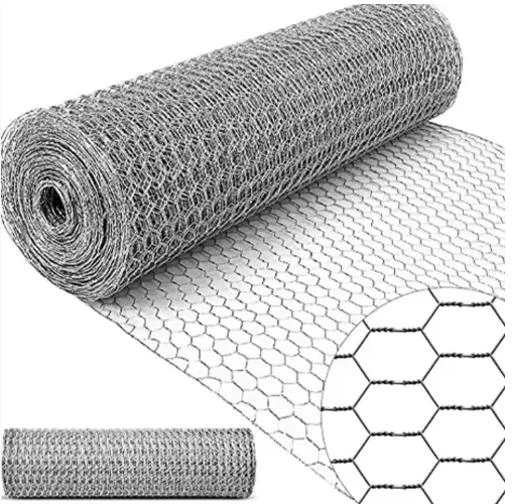

tie metal wire

Tying metal wire is an essential skill across numerous industries, from construction and metallurgy to everyday DIY projects. Mastery in handling and utilizing metal wire not only facilitates the creation of strong, enduring structures but also enhances the safety and efficiency of any project. Given the varied types of metal wire available, understanding the specifics of each type and its applications can significantly impact the quality and success of your work.

Furthermore, it’s beneficial to be acquainted with the concept of cantilever structures when using metal wire in architectural projects. By understanding the principles of tension and compression, one can effectively utilize the wire to manage load distribution efficiently. Such knowledge is vital in creating stable, well-supported structures. Incorporating new technology, such as CAD (Computer-Aided Design) software, can enhance precision in projects involving metal wire. CAD programs allow for precise modeling and simulation, aiding in anticipating and solving potential issues before they arise in real-world applications. Using such software fosters innovation and efficiency, providing an edge over traditional manual methods. In terms of safety, always wear appropriate personal protective equipment (PPE) and ensure that the workspace is free of any hazards. Regular inspections and maintenance of tools ensure their longevity and reliability. Additionally, ongoing training and skill development are paramount. Courses focusing on metalwork and engineering principles can bolster an individual's competencies, enhancing both practical and theoretical knowledge. Lastly, understanding and adhering to local building codes and regulations is non-negotiable. Compliance not only ensures the safety and structural integrity of projects but also reinforces trust and credibility among clients and stakeholders. In conclusion, tying metal wire is more than merely a connection between two points; it is a foundational skill that supports the broader architecture and functionality of countless projects. Through the acquisition of appropriate tools, techniques, and knowledge, tying metal wire becomes an art form, underpinned by expertise and authority. With careful consideration of material properties and environmental factors, your projects can achieve the highest standards of safety, durability, and efficiency while fostering trust and authority in the field.

Furthermore, it’s beneficial to be acquainted with the concept of cantilever structures when using metal wire in architectural projects. By understanding the principles of tension and compression, one can effectively utilize the wire to manage load distribution efficiently. Such knowledge is vital in creating stable, well-supported structures. Incorporating new technology, such as CAD (Computer-Aided Design) software, can enhance precision in projects involving metal wire. CAD programs allow for precise modeling and simulation, aiding in anticipating and solving potential issues before they arise in real-world applications. Using such software fosters innovation and efficiency, providing an edge over traditional manual methods. In terms of safety, always wear appropriate personal protective equipment (PPE) and ensure that the workspace is free of any hazards. Regular inspections and maintenance of tools ensure their longevity and reliability. Additionally, ongoing training and skill development are paramount. Courses focusing on metalwork and engineering principles can bolster an individual's competencies, enhancing both practical and theoretical knowledge. Lastly, understanding and adhering to local building codes and regulations is non-negotiable. Compliance not only ensures the safety and structural integrity of projects but also reinforces trust and credibility among clients and stakeholders. In conclusion, tying metal wire is more than merely a connection between two points; it is a foundational skill that supports the broader architecture and functionality of countless projects. Through the acquisition of appropriate tools, techniques, and knowledge, tying metal wire becomes an art form, underpinned by expertise and authority. With careful consideration of material properties and environmental factors, your projects can achieve the highest standards of safety, durability, and efficiency while fostering trust and authority in the field.

Next:

Latest news

-

Wire Mesh for Every Need: A Practical SolutionNewsJul.25,2025

-

Steel Fences: Durable, Secure, and Stylish OptionsNewsJul.25,2025

-

Roll Top Fencing: A Smart Solution for Safety and SecurityNewsJul.25,2025

-

Cattle Farm Fencing Solutions for Maximum SecurityNewsJul.25,2025

-

Affordable Iron Binding Wire SolutionsNewsJul.25,2025

-

Affordable Galvanized Wire SolutionsNewsJul.25,2025

-

Wire Hanger Recycling IdeasNewsJul.25,2025

Related PRODUCTS