-

Phone:

Phone: -

Email:

Email:

Innovative Solutions for High-Strength Tie Steel Wire Applications and Benefits

The Versatility and Applications of Tie Steel Wire

Tie steel wire, often referred to simply as tie wire, is a critical component in various construction and manufacturing processes. This versatile material is made from high-quality steel and is primarily used for binding, fastening, and reinforcing materials in a variety of applications. In this article, we will delve into the properties, manufacturing processes, and numerous applications of tie steel wire, showcasing its importance across different industries.

Properties of Tie Steel Wire

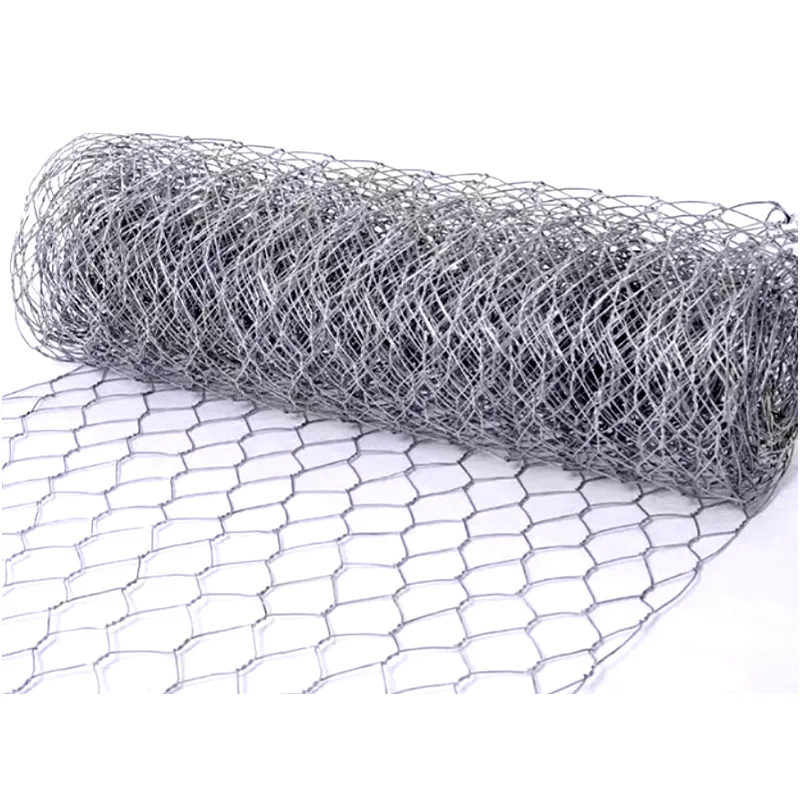

Tie steel wire is characterized by its exceptional strength and durability. Typically made from carbon steel, it exhibits high tensile strength, making it ideal for applications that require reliable binding capabilities. The wire can withstand tension and external forces, thereby ensuring the integrity of structures it supports. Additionally, tie steel wire is often coated with materials such as galvanized zinc to enhance its resistance to corrosion, ensuring a longer lifespan even in harsh environmental conditions.

The diameter of tie steel wire can vary from thin gauges (such as 14 to 18 gauge) to thicker ones (up to 8 gauge), providing flexibility for different construction needs. The wire is available in coils or straightened lengths, making it convenient for various uses. Its malleability allows it to be easily bent and shaped, which is a significant advantage in binding and tying applications.

Manufacturing Process

The production of tie steel wire involves several processes, starting from the selection of high-quality raw steel. The raw steel is drawn through a series of dies to achieve the desired diameter. This drawing process not only reduces the diameter but also increases the wire's strength due to the work-hardening effect. Once the wire reaches its specified thickness, it is often treated to enhance its properties, such as galvanization, which provides a protective layer against rust and corrosion.

tie steel wire

After treatment, the wire is cut into lengths or wound into coils, depending on its intended use. Quality control is an essential aspect of the manufacturing process, ensuring that the wire meets industry standards and specifications. This meticulous production process results in a product that is reliable and efficient for various applications.

Applications of Tie Steel Wire

Tie steel wire has a myriad of applications across different sectors, particularly in construction and manufacturing. One of its primary uses is in the construction industry, where it serves as a fundamental element for reinforcing concrete structures. The wire is often used to tie rebar (reinforcing bars) together, ensuring that the reinforcing framework remains intact during the pouring of concrete. This application is crucial in enhancing the structural integrity of buildings, bridges, and other infrastructure.

In addition to construction, tie steel wire is extensively used in landscaping. It serves as a binding agent for trellises, supporting plants and vines as they grow. Farmers and gardeners also rely on tie wire to secure plants, create fencing, and construct various types of supports for different plants.

The manufacturing sector utilizes tie steel wire in various mechanical applications. It is commonly employed for hanging and holding components together during assembly processes. Additionally, tie wire is often used in the automotive industry for securing components and systems due to its reliability and strength.

Conclusion

In conclusion, tie steel wire is an indispensable material in modern construction and manufacturing. Its unique properties, such as high tensile strength and versatility, make it suitable for a wide array of applications. From reinforcing concrete structures to supporting plants in gardens, tie steel wire continues to play a crucial role in both industrial and everyday applications. As industries evolve and demand for reliable materials grows, the importance of tie steel wire remains steadfast, proving its worth as a vital component in various fields.

-

Wire Mesh for Every Need: A Practical SolutionNewsJul.25,2025

-

Steel Fences: Durable, Secure, and Stylish OptionsNewsJul.25,2025

-

Roll Top Fencing: A Smart Solution for Safety and SecurityNewsJul.25,2025

-

Cattle Farm Fencing Solutions for Maximum SecurityNewsJul.25,2025

-

Affordable Iron Binding Wire SolutionsNewsJul.25,2025

-

Affordable Galvanized Wire SolutionsNewsJul.25,2025

-

Wire Hanger Recycling IdeasNewsJul.25,2025