-

Phone:

Phone: -

Email:

Email:

tie steel wire

The Versatility and Durability of Tie Steel Wire

Tie steel wire is an essential material widely used in various construction and manufacturing applications. Its robust properties make it a preferred choice for both professional contractors and DIY enthusiasts. This article explores the significance, applications, manufacturing process, and benefits of tie steel wire.

Understanding Tie Steel Wire

Tie steel wire, also known as binding wire, is typically made from high-carbon steel and is manufactured in various gauges and strengths. The wire is pliable, allowing it to be easily bent and shaped to meet the needs of different tasks. Its main function is to bind or tie together materials, providing stability and support during construction.

Applications of Tie Steel Wire

One of the primary uses of tie steel wire is in the construction industry. It plays a crucial role in reinforcing concrete structures by holding together rebar and other components during the pouring process. This reinforcement is critical for ensuring the structural integrity and longevity of buildings, bridges, and other infrastructure.

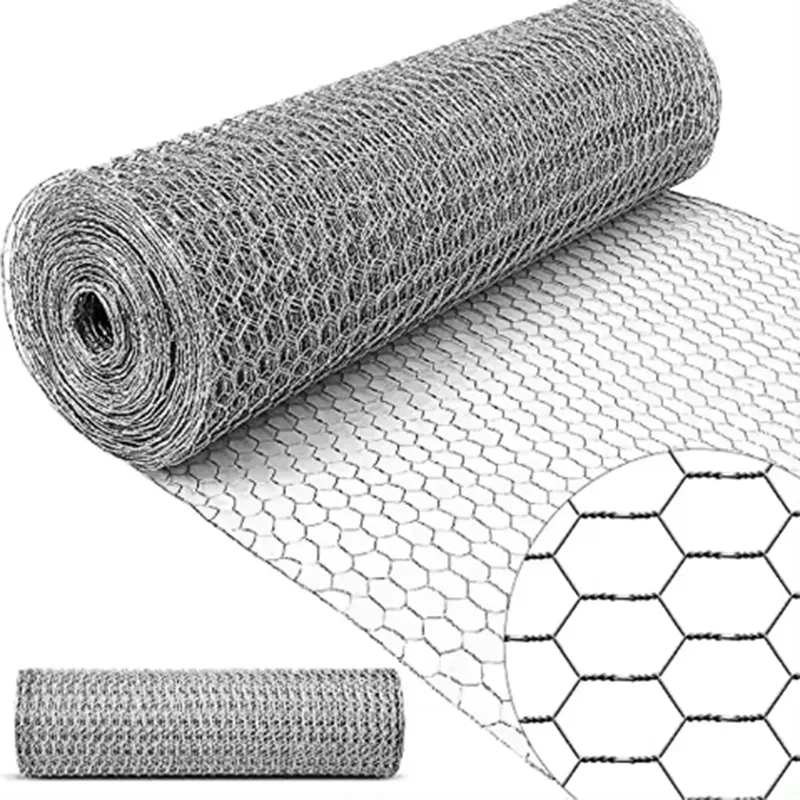

In addition to construction, tie steel wire finds its place in a variety of other sectors. It is extensively used in the manufacturing of wire mesh, which is critical in applications ranging from fencing to HVAC systems. The automotive industry also utilizes tie steel wire for securing components in assembly processes. Furthermore, agricultural sectors employ this wire for tying plants and fencing, showcasing its versatility.

The Manufacturing Process

tie steel wire

The production of tie steel wire involves a series of steps that ensure its quality and reliability. The process typically begins with the selection of high-grade steel to guarantee strength and flexibility. Once the steel is chosen, it undergoes a drawing process where it is pulled through a series of dies to achieve the desired diameter and strength.

After drawing, the wire is often treated through processes such as annealing, which involves heating it to soften and improve its ductility. This step is crucial as it allows the wire to be easily manipulated without breaking. Once treated, the wire is wound onto spools and packaged for distribution. Quality control is essential during manufacturing to ensure the wire meets industry standards and customer specifications.

Benefits of Tie Steel Wire

Tie steel wire offers numerous advantages that make it the go-to choice for many applications. First and foremost, its high tensile strength provides exceptional support, ensuring that structures remain stable under various loads. Additionally, tie steel wire is resistant to corrosion when properly coated, extending its lifespan and durability in outdoor or damp environments.

Another significant benefit is its cost-effectiveness. Tie steel wire is relatively inexpensive compared to other materials, making it an economical option for large-scale projects. Its lightweight nature also contributes to lower shipping and handling costs.

Moreover, the ease of use of tie steel wire cannot be understated. Its malleability allows workers to quickly and efficiently tie and secure materials without the need for extensive tools or equipment. This flexibility speeds up construction processes and enhances productivity on job sites.

Conclusion

In conclusion, tie steel wire is a vital component in various industries, particularly in construction and manufacturing. Its strength, versatility, and ease of use underscore its importance as a reliable binding material. As technology and construction methods continue to evolve, the demand for tie steel wire will likely persist, reinforcing its role as a cornerstone in building the world around us. Whether it's for constructing robust frameworks or simple agricultural tasks, tie steel wire remains an indispensable resource, underscoring the blend of tradition and innovation in material applications.

-

Wire Mesh for Every Need: A Practical SolutionNewsJul.25,2025

-

Steel Fences: Durable, Secure, and Stylish OptionsNewsJul.25,2025

-

Roll Top Fencing: A Smart Solution for Safety and SecurityNewsJul.25,2025

-

Cattle Farm Fencing Solutions for Maximum SecurityNewsJul.25,2025

-

Affordable Iron Binding Wire SolutionsNewsJul.25,2025

-

Affordable Galvanized Wire SolutionsNewsJul.25,2025

-

Wire Hanger Recycling IdeasNewsJul.25,2025