-

Phone:

Phone: -

Email:

Email:

Feb . 17, 2025 14:55

Back to list

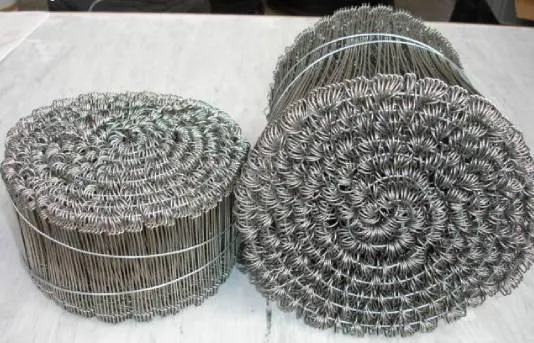

Loop Tie Wire

Understanding the nuances of tie steel wire can significantly enhance your construction projects, especially if you're determined to achieve high efficacy and reliability. Steel wire, particularly when used for tying, serves vital roles in various domains such as construction, agriculture, and even art. This article delves into the intricacies of tie steel wire, offering insights into its properties, applications, and selection criteria to ensure optimal performance.

When selecting tie steel wire, understanding its technical specifications is paramount. Attributes such as the gauge, coating, and tensile strength determine its suitability for specific tasks. For example, construction tasks requiring high load-bearing capacity will benefit from thicker gauges with superior tensile properties. Conversely, for delicate artistic work, a fine gauge offering greater flexibility and maneuverability might be ideal. Moreover, tie steel wire's reliability extends to its cost-effectiveness and ease of use. It can be manually manipulated or utilized with automatic tying tools, which streamline the process and boost efficiency. The market offers an array of such tools that not only enhance the speed of tying but also improve the consistency and security of each tie. Sustainability also factors into the consideration of using tie steel wire. Many manufacturers offer products made from recycled steel, contributing to environmental conservation efforts. Sustainable procurement can additionally earn construction projects green certification and enhance their overall eco-friendliness. In summary, tie steel wire serves a multifaceted role across industries, and its importance cannot be overstated. Its strength, adaptability, and versatility make it an indispensable element in securing structural components, supporting agricultural activities, and enabling artistic expression. When selecting the right steel wire, consider both the immediate requirements of your project and the broader implications of durability and environmental impact. By doing so, you ensure not only the success and longevity of your endeavors but also contribute positively to sustainable practices in material usage.

When selecting tie steel wire, understanding its technical specifications is paramount. Attributes such as the gauge, coating, and tensile strength determine its suitability for specific tasks. For example, construction tasks requiring high load-bearing capacity will benefit from thicker gauges with superior tensile properties. Conversely, for delicate artistic work, a fine gauge offering greater flexibility and maneuverability might be ideal. Moreover, tie steel wire's reliability extends to its cost-effectiveness and ease of use. It can be manually manipulated or utilized with automatic tying tools, which streamline the process and boost efficiency. The market offers an array of such tools that not only enhance the speed of tying but also improve the consistency and security of each tie. Sustainability also factors into the consideration of using tie steel wire. Many manufacturers offer products made from recycled steel, contributing to environmental conservation efforts. Sustainable procurement can additionally earn construction projects green certification and enhance their overall eco-friendliness. In summary, tie steel wire serves a multifaceted role across industries, and its importance cannot be overstated. Its strength, adaptability, and versatility make it an indispensable element in securing structural components, supporting agricultural activities, and enabling artistic expression. When selecting the right steel wire, consider both the immediate requirements of your project and the broader implications of durability and environmental impact. By doing so, you ensure not only the success and longevity of your endeavors but also contribute positively to sustainable practices in material usage.

Latest news

-

Wire Mesh for Every Need: A Practical SolutionNewsJul.25,2025

-

Steel Fences: Durable, Secure, and Stylish OptionsNewsJul.25,2025

-

Roll Top Fencing: A Smart Solution for Safety and SecurityNewsJul.25,2025

-

Cattle Farm Fencing Solutions for Maximum SecurityNewsJul.25,2025

-

Affordable Iron Binding Wire SolutionsNewsJul.25,2025

-

Affordable Galvanized Wire SolutionsNewsJul.25,2025

-

Wire Hanger Recycling IdeasNewsJul.25,2025

Related PRODUCTS