-

Phone:

Phone: -

Email:

Email:

Feb . 11, 2025 07:05

Back to list

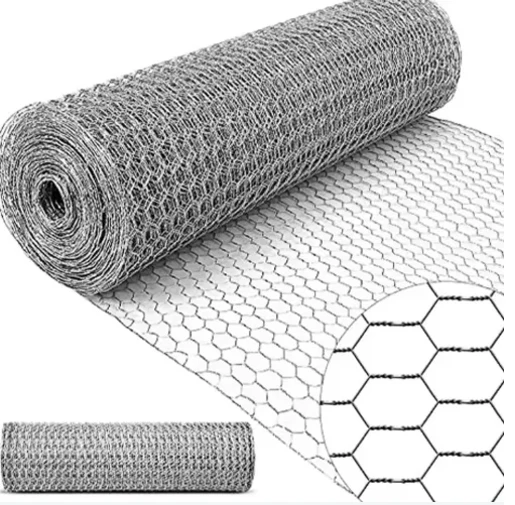

tie wire per kg of rebar

The selection and use of tie wire for securing rebar in construction projects are crucial elements that can significantly impact the overall stability and safety of a structure. With technology continuously advancing and the construction industry's need for safe, reliable methods increasing, professionals need a deep understanding of tie wire usage per kilogram of rebar to ensure optimal performance.

Another critical aspect to consider is the gauge of the tie wire. Commonly used gauges, such as 16 or 18, provide varying levels of flexibility and strength. Thicker wire, while more durable, can be more challenging and time-consuming to work with, impacting the overall efficiency of a project. Technology has begun to play a transformative role in the use of tie wire. Automated rebar tying machines have been introduced to enhance efficiency and consistency. These machines can reduce labor costs, minimize the physical toll on workers, and ensure uniformity across large projects. By using automated rebar tying machines, projects can be completed with reduced amounts of waste and a more efficient use of tie wire per kilogram of rebar. The experience of selecting and applying tie wire also translates into better project outcomes. Skilled workers can minimize waste, ensure optimal use of materials, and enhance safety, directly contributing to project success. Investing in training for workers to better understand the properties of tie wire and the implications of their application techniques can yield substantial benefits. Monitoring advancements in material science and technology is essential for construction professionals. New materials or improved designs in tie wire can offer enhanced durability or ease of use, which translate to cost savings and improved safety. Professionals should stay informed about these advancements through continuous learning and engagement with industry bodies. To conclude, understanding the usage of tie wire per kilogram of rebar transcends simple construction logistics—it involves an intricate blend of material science, practical expertise, and strategic decision-making. As the construction landscape evolves, the role of tie wire remains vital. Proper planning and execution regarding tie wire can lead to better efficiency, safety, and ultimately, the success of construction projects. Building professionals should harness experience, expertise, and emerging technologies to optimize their use of tie wire, ensuring that structures stand the test of time while concurrently meeting the stringent demands of modern construction.

Another critical aspect to consider is the gauge of the tie wire. Commonly used gauges, such as 16 or 18, provide varying levels of flexibility and strength. Thicker wire, while more durable, can be more challenging and time-consuming to work with, impacting the overall efficiency of a project. Technology has begun to play a transformative role in the use of tie wire. Automated rebar tying machines have been introduced to enhance efficiency and consistency. These machines can reduce labor costs, minimize the physical toll on workers, and ensure uniformity across large projects. By using automated rebar tying machines, projects can be completed with reduced amounts of waste and a more efficient use of tie wire per kilogram of rebar. The experience of selecting and applying tie wire also translates into better project outcomes. Skilled workers can minimize waste, ensure optimal use of materials, and enhance safety, directly contributing to project success. Investing in training for workers to better understand the properties of tie wire and the implications of their application techniques can yield substantial benefits. Monitoring advancements in material science and technology is essential for construction professionals. New materials or improved designs in tie wire can offer enhanced durability or ease of use, which translate to cost savings and improved safety. Professionals should stay informed about these advancements through continuous learning and engagement with industry bodies. To conclude, understanding the usage of tie wire per kilogram of rebar transcends simple construction logistics—it involves an intricate blend of material science, practical expertise, and strategic decision-making. As the construction landscape evolves, the role of tie wire remains vital. Proper planning and execution regarding tie wire can lead to better efficiency, safety, and ultimately, the success of construction projects. Building professionals should harness experience, expertise, and emerging technologies to optimize their use of tie wire, ensuring that structures stand the test of time while concurrently meeting the stringent demands of modern construction.

Next:

Latest news

-

Wire Mesh for Every Need: A Practical SolutionNewsJul.25,2025

-

Steel Fences: Durable, Secure, and Stylish OptionsNewsJul.25,2025

-

Roll Top Fencing: A Smart Solution for Safety and SecurityNewsJul.25,2025

-

Cattle Farm Fencing Solutions for Maximum SecurityNewsJul.25,2025

-

Affordable Iron Binding Wire SolutionsNewsJul.25,2025

-

Affordable Galvanized Wire SolutionsNewsJul.25,2025

-

Wire Hanger Recycling IdeasNewsJul.25,2025

Related PRODUCTS