-

Phone:

Phone: -

Email:

Email:

what is baling wire used for

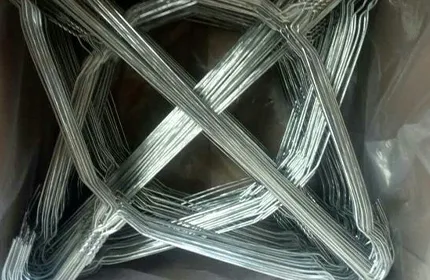

Understanding Baling Wire and Its Uses

Baling wire is a robust and versatile material commonly used in various industries for binding and securing products in compact bundles. Its primary function is to hold bales of different materials together, facilitating easier handling, storage, and transportation. This article explores the various uses of baling wire, its characteristics, and why it is an essential component in numerous applications.

What is Baling Wire?

Baling wire is typically made from high-quality steel and is available in different gauges and strengths depending on its intended use. The wire is designed to withstand significant tension and pressure, making it ideal for securing bales of materials like hay, cardboard, paper, textiles, and metal scraps. Baling wire can be found in both pre-cut lengths and rolls, allowing for flexibility in its application.

Key Uses of Baling Wire

1. Agriculture In the agricultural sector, baling wire is predominantly used to tie bales of hay, straw, and fodder. Farmers rely on it to keep their livestock feed securely bundled, which aids in storage and transportation. Properly tied bales not only save space but also prevent spoilage and damage from weather conditions.

2. Recycling and Waste Management Baling wire plays a critical role in recycling facilities where materials such as paper, plastics, and metals are sorted and baled for shipment to processing plants. By securing these materials into compact bales, baling wire helps optimize space in transportation and improves the efficiency of recycling operations.

what is baling wire used for

3. Manufacturing In manufacturing industries, baling wire is often used to package finished goods or components. For example, construction materials like rebar and wire mesh are bundled using baling wire to ensure they remain intact during shipping and storage. This minimizes the risk of damage and improves logistical efficiency.

4. Shipping and Logistics Baling wire is also utilized in the logistics sector for securing goods on pallets or in containers. By tying down multiple items together, it prevents movement during transit, reducing the likelihood of damage and enhancing safety. This is especially crucial for fragile or heavy items that require additional support.

5. Crafting and DIY Projects Beyond industrial uses, baling wire is a popular choice for crafters and DIY enthusiasts. Its flexibility allows users to manipulate it into various shapes and sizes for artistic projects, while its strength ensures durability. Whether it is used for creating structures, sculptures, or decorative pieces, baling wire’s versatility is a boon for creative expression.

Advantages of Baling Wire

The advantages of using baling wire are numerous. Its high tensile strength ensures that it can hold heavy loads securely without breaking. Additionally, baling wire is cost-effective; its durability means that it can be reused multiple times, reducing the need for frequent replacements. Moreover, it is available in various sizes and thicknesses, catering to different needs and applications.

Conclusion

Baling wire is an indispensable tool across multiple industries, providing a reliable solution for bundling, securing, and transporting goods. From agriculture to recycling and creative pursuits, its utility is vast and varied. By understanding the applications of baling wire, businesses and individuals can make informed choices about employing this versatile material in their operations and projects. As industries continue to evolve, the demand for effective binding solutions like baling wire will undoubtedly remain strong.

-

Wire Mesh for Every Need: A Practical SolutionNewsJul.25,2025

-

Steel Fences: Durable, Secure, and Stylish OptionsNewsJul.25,2025

-

Roll Top Fencing: A Smart Solution for Safety and SecurityNewsJul.25,2025

-

Cattle Farm Fencing Solutions for Maximum SecurityNewsJul.25,2025

-

Affordable Iron Binding Wire SolutionsNewsJul.25,2025

-

Affordable Galvanized Wire SolutionsNewsJul.25,2025

-

Wire Hanger Recycling IdeasNewsJul.25,2025