-

Phone:

Phone: -

Email:

Email:

Top Wire Coat Hanger Manufacturers for Your Home or Business Needs

Exploring the World of Wire Coat Hanger Manufacturers Quality, Innovation, and Sustainability

Wire coat hangers, often seen as mundane household items, play a crucial role in our daily lives. They keep our clothes organized, wrinkle-free, and ready to wear. Despite their simplicity, the manufacturing of wire coat hangers has evolved significantly over the years, marked by innovation, quality improvements, and a growing emphasis on sustainability. In this article, we will delve into the world of wire coat hanger manufacturers, exploring their practices, challenges, and the future of this ubiquitous product.

The Manufacturing Process

The production of wire coat hangers begins with the selection of high-quality wire materials, typically made from steel or stainless steel. Manufacturers must ensure that the wire is strong yet flexible enough to hold various types of garments without deforming. The wire undergoes a series of processes, including cutting, bending, and welding, to form the familiar shape of the hanger. Advanced machinery and automation have streamlined these processes, allowing manufacturers to produce large quantities efficiently while maintaining quality standards.

Innovative designs have also emerged from manufacturers looking to cater to specific consumer needs. For instance, some brands have developed hangers with added features like non-slip grips, specialized clips for skirts or pants, and even adjustable widths to accommodate different clothing styles. Manufacturers are constantly investing in research and development to create designs that not only enhance functionality but also appeal to consumers' aesthetic preferences.

Quality Control

Quality control is paramount in the manufacturing process of wire coat hangers. Manufacturers implement rigorous quality assurance measures to ensure that the hangers can withstand daily use. This includes testing the strength of the wire, checking for sharp edges, and ensuring that the finish is smooth to prevent snags on clothing. High-quality hangers not only protect garments but also enhance the overall hanging experience for consumers.

To stand out in a competitive market, manufacturers often pursue certifications and standards that reflect their commitment to quality. ISO certifications, for instance, indicate that a manufacturer adheres to international quality management standards, reassuring consumers of the durability and reliability of the products.

wire coat hanger manufacturers

Sustainability in Wire Coat Hanger Manufacturing

In recent years, sustainability has become a central focus for wire coat hanger manufacturers. As the fashion industry grapples with environmental concerns, manufacturers are being urged to minimize waste and reduce their carbon footprint. This has led to several changes in the manufacturing process, including the sourcing of eco-friendly materials and the recycling of scrap wire generated during production.

Some manufacturers have started to explore biodegradable or recyclable coatings for their hangers, further enhancing their sustainability credentials. Additionally, manufacturers are increasingly adopting practices that reduce energy consumption in their facilities, such as utilizing energy-efficient machinery and optimizing production processes.

Challenges Faced by Manufacturers

Despite advancements in technology and sustainability efforts, wire coat hanger manufacturers face several challenges. The fluctuating costs of raw materials can impact profit margins, making it essential for manufacturers to have effective supply chain management in place. Moreover, competition from cheaper alternatives, such as plastic hangers, poses a significant challenge. Manufacturers must convey the value of wire hangers, emphasizing their durability, style, and environmental benefits over plastic options.

The Future of Wire Coat Hanger Manufacturing

Looking ahead, the future of wire coat hanger manufacturing appears promising. As consumer preferences shift toward more sustainable products, manufacturers who embrace eco-friendly practices are likely to thrive. The integration of technology, such as 3D printing and smart manufacturing, may also revolutionize the production process, allowing for more customized and innovative designs.

Ultimately, the wire coat hanger may seem like a simple product, but its manufacturing encompasses a complex interplay of quality, innovation, and sustainable practices. As manufacturers navigate challenges and embrace opportunities, they will continue to play a vital role in the fashion and clothing storage industries, ensuring that everyday items meet the evolving needs of consumers worldwide.

-

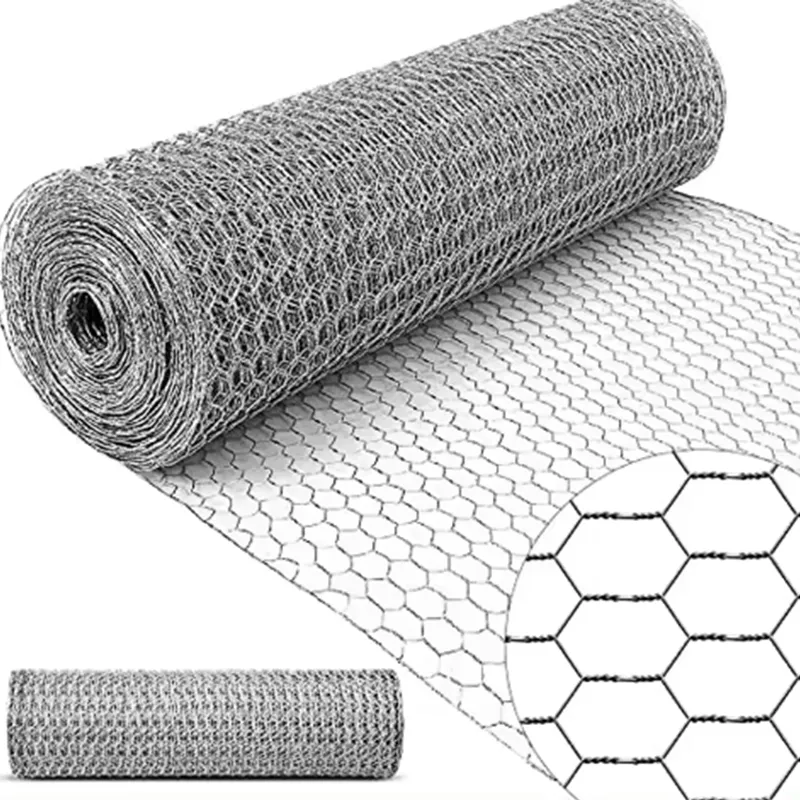

Wire Mesh for Every Need: A Practical SolutionNewsJul.25,2025

-

Steel Fences: Durable, Secure, and Stylish OptionsNewsJul.25,2025

-

Roll Top Fencing: A Smart Solution for Safety and SecurityNewsJul.25,2025

-

Cattle Farm Fencing Solutions for Maximum SecurityNewsJul.25,2025

-

Affordable Iron Binding Wire SolutionsNewsJul.25,2025

-

Affordable Galvanized Wire SolutionsNewsJul.25,2025

-

Wire Hanger Recycling IdeasNewsJul.25,2025