-

Phone:

Phone: -

Email:

Email:

Top Wire Coat Hanger Producers and Their Innovative Manufacturing Techniques

The Wire Coat Hanger Manufacturing Industry

Wire coat hangers have become a staple in households around the world. They serve a simple yet essential purpose—keeping our clothing organized and wrinkle-free. The manufacturing of wire coat hangers involves a specialized process that not only ensures quality but also adapts to the diverse needs of consumers. This article explores the wire coat hanger manufacturing industry, touching upon materials, processes, market demands, and sustainability.

The Wire Coat Hanger Manufacturing Industry

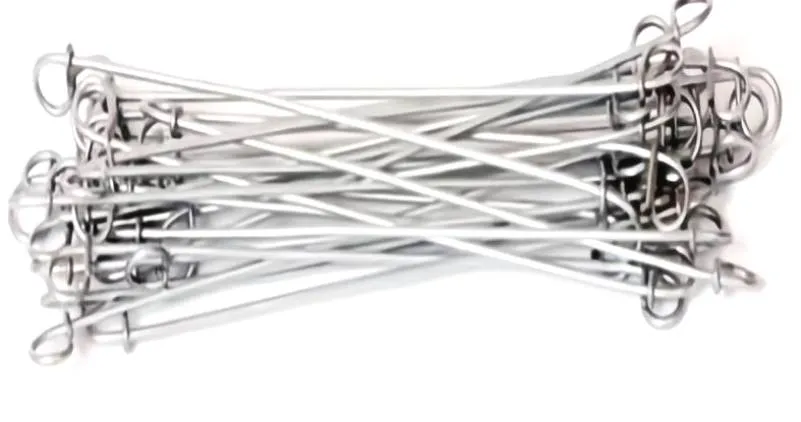

The manufacturing process begins with wire drawing, where large coils of steel are drawn through a series of dies to achieve the desired thickness. Next, the wire is cut to specific lengths based on the design of the hanger. The bending and shaping processes follow, where machines or manual labor create the characteristic shape of the hanger, incorporating features such as notches for straps and hooks for easy storage.

wire coat hanger manufacturers

Once the basic shape is formed, the hangers are often coated with a layer of plastic or paint for added protection and aesthetic appeal. This coating not only enhances durability but also allows for customization in colors and finishes, catering to varying consumer preferences. Manufacturers increasingly offer eco-friendly options, utilizing sustainable materials and non-toxic coatings to meet environmental standards and consumer demand for green products.

The market for wire coat hangers has evolved, influenced by trends in fashion, interior design, and consumer lifestyle. Increasingly, manufacturers are required to produce hangers that not only serve their functional purpose but also complement modern home décor. As a result, many companies are diversifying their product lines to include decorative and collapsible options.

Moreover, the rise of e-commerce has impacted the distribution of wire coat hangers. Manufacturers are now focusing on online sales channels, providing bulk purchasing options for retailers and individual consumers alike. This shift emphasizes the need for efficient packaging and shipping methods to minimize environmental impact and enhance customer satisfaction.

In conclusion, wire coat hanger manufacturers play a crucial role in the fashion and home goods industries. With a focus on quality materials, innovative designs, and sustainability, these manufacturers are adapting to the changing demands of modern consumers while maintaining the essential functionality that wire coat hangers provide. As trends continue to evolve, so too will the methods and materials used in this industrious sector.

-

Wire Mesh for Every Need: A Practical SolutionNewsJul.25,2025

-

Steel Fences: Durable, Secure, and Stylish OptionsNewsJul.25,2025

-

Roll Top Fencing: A Smart Solution for Safety and SecurityNewsJul.25,2025

-

Cattle Farm Fencing Solutions for Maximum SecurityNewsJul.25,2025

-

Affordable Iron Binding Wire SolutionsNewsJul.25,2025

-

Affordable Galvanized Wire SolutionsNewsJul.25,2025

-

Wire Hanger Recycling IdeasNewsJul.25,2025