-

Phone:

Phone: -

Email:

Email:

wire handles manufacturer

The Role of Wire Handles in Modern Manufacturing A Look at Wire Handle Manufacturers

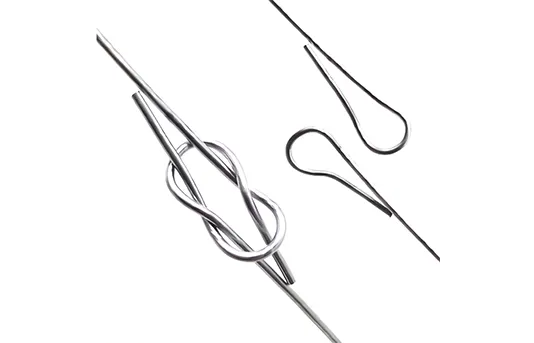

In industrial manufacturing and product development, the details often make the difference. One such detail that plays a crucial role in various products is the wire handle. Wire handles are essential components used in a wide array of items, from baskets and containers to luggage and tools. As demand for lightweight yet durable solutions increases, wire handle manufacturers are stepping up to meet the needs of diverse industries.

Wire handles are typically made from high-strength steel, stainless steel, or aluminum. These materials are chosen for their durability and resistance to corrosion, making them ideal for both indoor and outdoor applications. Manufacturers employ advanced techniques such as welding, bending, and coating to ensure that wire handles not only function effectively but also enhance the aesthetic appeal of the products they accompany.

The Role of Wire Handles in Modern Manufacturing A Look at Wire Handle Manufacturers

In addition to customization, innovation is a driving force in the wire handle manufacturing industry. Manufacturers are increasingly incorporating ergonomic designs to improve user comfort and practicality. This is especially important in consumer products, where ease of use can significantly impact customer satisfaction. Advanced materials, such as polymer coatings, are being explored to provide better grip, reducing the risk of slipping during use.

wire handles manufacturer

Sustainability is another key trend influencing wire handle manufacturers today. As environmental concerns grow, manufacturers are investigating eco-friendly materials and processes. By recycling scrap metal and using sustainable production practices, manufacturers not only contribute to environmental preservation but can also appeal to eco-conscious consumers.

In a competitive market, wire handle manufacturers must innovate continually. They not only face the challenge of optimizing production efficiency but also the task of maintaining product quality. Implementing strict quality control measures throughout the manufacturing process ensures that each wire handle meets the necessary safety and durability standards.

As we move further into the 21st century, the wire handle manufacturing industry is set to evolve alongside technological advancements. Automation and robotics may play a more significant role in production, leading to increased efficiency and reduced costs.

In conclusion, wire handles are critical components that facilitate product functionality and usability across various sectors. Wire handle manufacturers are pivotal in developing solutions that meet changing consumer demands, prioritize sustainability, and adhere to quality standards. As innovation continues in this field, the future looks bright for wire handle production and its vital role in the manufacturing landscape.

-

Wire Mesh for Every Need: A Practical SolutionNewsJul.25,2025

-

Steel Fences: Durable, Secure, and Stylish OptionsNewsJul.25,2025

-

Roll Top Fencing: A Smart Solution for Safety and SecurityNewsJul.25,2025

-

Cattle Farm Fencing Solutions for Maximum SecurityNewsJul.25,2025

-

Affordable Iron Binding Wire SolutionsNewsJul.25,2025

-

Affordable Galvanized Wire SolutionsNewsJul.25,2025

-

Wire Hanger Recycling IdeasNewsJul.25,2025