-

Phone:

Phone: -

Email:

Email:

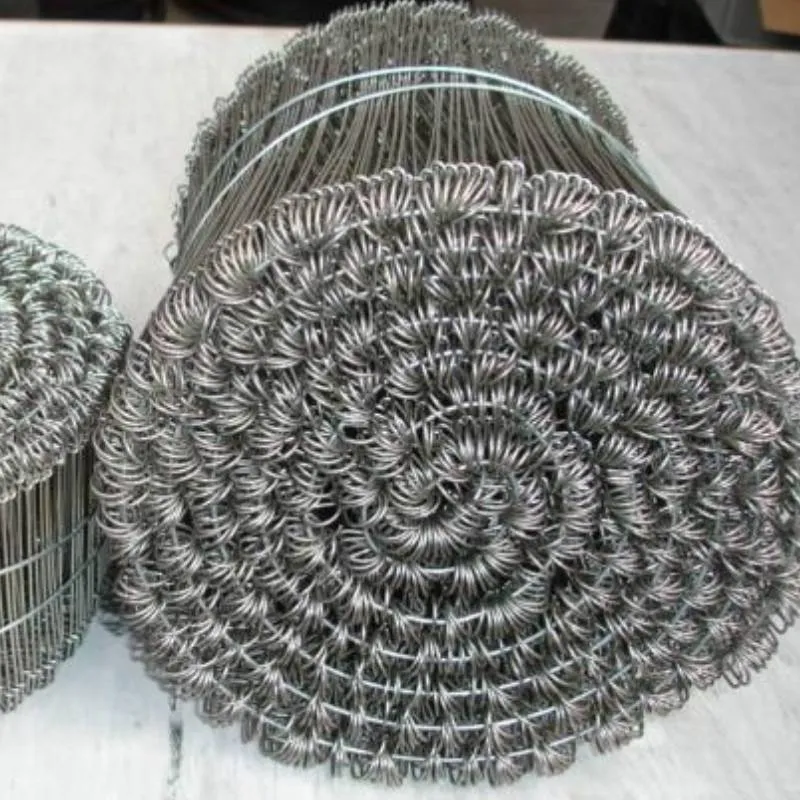

wire handles manufacturer

Understanding Wire Handles A Comprehensive Look at Manufacturers

Wire handles are essential components in various industries, serving the functional purpose of providing grip and support to objects. Manufactured from durable materials such as steel or aluminum, wire handles are designed to withstand significant stress while remaining lightweight. This article examines the wire handles manufacturing industry, exploring the significance of these components, the manufacturing process, and the impact of industry standards on quality.

Understanding Wire Handles A Comprehensive Look at Manufacturers

The manufacturing process of wire handles involves several steps, starting with material selection. Manufacturers typically choose high-quality wire materials to ensure strength and durability. Once the wire is selected, it undergoes processes such as cutting, bending, and shaping. Advanced machinery is employed to create the desired shape and structure, ensuring consistency and precision in every handle produced. Computer Numerical Control (CNC) machines are often utilized to enhance the efficiency of production and achieve intricate designs that meet the specific needs of clients.

wire handles manufacturer

After the handles are shaped, they undergo finishing processes that may include welding, coating, or plating. These finishes not only enhance the aesthetic appeal of the wire handles but also protect them from environmental factors like rust and corrosion. Quality control is a crucial aspect of the manufacturing process, ensuring that each handle meets the required specifications and standards. Manufacturers often conduct rigorous testing to assess the strength and durability of the wire handles before they reach the market.

As with any manufacturing sector, compliance with industry standards is paramount in the wire handle manufacturing industry. Standards set by organizations such as the International Organization for Standardization (ISO) ensure that products are safe, reliable, and of high quality. Companies that adhere to these standards are often able to market their products more effectively, gaining a competitive edge in the marketplace.

The wire handle manufacturing industry is continually evolving, driven by advancements in technology and changing consumer demands. The rise of sustainability has prompted manufacturers to explore eco-friendly materials, reducing the environmental impact of production processes. As businesses seek to minimize waste and embrace circular economy principles, the future of wire handle manufacturing is increasingly focused on innovation and sustainability.

In conclusion, wire handles are integral to various industries, providing essential functionality while enhancing the ease of transport and usability of products. The manufacturing processes involved are complex and require a keen eye for detail, ensuring that quality and durability are always paramount. As technology advances and consumer preferences shift, wire handle manufacturers will need to adapt, focusing on creating sustainable solutions that meet the evolving needs of their clients. With a commitment to quality and innovation, the wire handle manufacturing sector is well-equipped to face the challenges and opportunities of the future.

-

Wire Mesh for Every Need: A Practical SolutionNewsJul.25,2025

-

Steel Fences: Durable, Secure, and Stylish OptionsNewsJul.25,2025

-

Roll Top Fencing: A Smart Solution for Safety and SecurityNewsJul.25,2025

-

Cattle Farm Fencing Solutions for Maximum SecurityNewsJul.25,2025

-

Affordable Iron Binding Wire SolutionsNewsJul.25,2025

-

Affordable Galvanized Wire SolutionsNewsJul.25,2025

-

Wire Hanger Recycling IdeasNewsJul.25,2025