-

Phone:

Phone: -

Email:

Email:

Фев . 14, 2025 03:19

Back to list

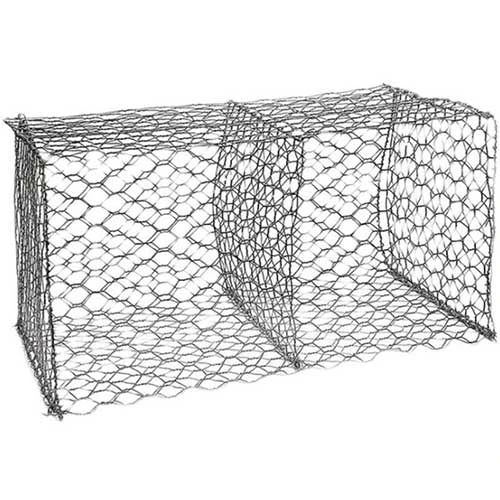

wire bucket handle

The wire bucket handle, seemingly a minor component, plays a crucial role in both domestic and industrial applications. Its design, strength, and functionality can enhance the overall utility of a bucket, making it indispensable for a variety of tasks. When selecting and utilizing a wire bucket handle, it's essential to consider the intricate blend of material science and engineering that goes into crafting a durable and efficient product.

Authoritativeness in this area comes from industry standards and certifications that ensure wire bucket handles meet specific safety and durability metrics. By adhering to these standards, manufacturers can assure consumers of the product's quality and reliability. This assurance helps build trust and establishes reputational integrity within the market. Organizations like the International Organization for Standardization (ISO) provide guidelines that many reputable manufacturers follow, thus establishing industry-wide benchmarks for quality and safety. Trustworthiness in wire bucket handle production is further reinforced through transparent manufacturing processes. Companies that showcase their sourcing of raw materials, manufacturing techniques, and quality assurance tests gain a competitive edge. Not only do they provide consumers with essential knowledge on product resilience and dependability, but they also demonstrate a commitment to environmental and ethical standards. Expertise in material science and mechanical engineering is pivotal in addressing the evolving needs of various sectors dependent on efficient carrying solutions. For example, wire bucket handles in the farming industry must endure not just weight but also constant exposure to the elements and rough handling. Engineers and designers continue to innovate, implementing new alloy compositions and structural designs that extend the life and improve the performance of these handles. Experience, accumulated over decades, informs the strategic improvements in wire bucket handle design. Feedback from end-users, whether they are construction workers, farmers, or homeowners, guides practical enhancements to handle durability and usability. Companies often employ teams dedicated to testing and refining these handles under diverse conditions, ensuring that each iteration addresses previous shortcomings while fulfilling emerging demands. In conclusion, the wire bucket handle exemplifies a blend of engineering finesse, practical design, and industry reliability. A critical component across numerous applications, its importance cannot be understated. By focusing on quality construction, ergonomic design, and robust safety standards, manufacturers not only meet but exceed the expectations of a diverse audience. The evolution and meticulous craftsmanship of wire bucket handles highlight an unsung hero essential to countless day-to-day operations.

Authoritativeness in this area comes from industry standards and certifications that ensure wire bucket handles meet specific safety and durability metrics. By adhering to these standards, manufacturers can assure consumers of the product's quality and reliability. This assurance helps build trust and establishes reputational integrity within the market. Organizations like the International Organization for Standardization (ISO) provide guidelines that many reputable manufacturers follow, thus establishing industry-wide benchmarks for quality and safety. Trustworthiness in wire bucket handle production is further reinforced through transparent manufacturing processes. Companies that showcase their sourcing of raw materials, manufacturing techniques, and quality assurance tests gain a competitive edge. Not only do they provide consumers with essential knowledge on product resilience and dependability, but they also demonstrate a commitment to environmental and ethical standards. Expertise in material science and mechanical engineering is pivotal in addressing the evolving needs of various sectors dependent on efficient carrying solutions. For example, wire bucket handles in the farming industry must endure not just weight but also constant exposure to the elements and rough handling. Engineers and designers continue to innovate, implementing new alloy compositions and structural designs that extend the life and improve the performance of these handles. Experience, accumulated over decades, informs the strategic improvements in wire bucket handle design. Feedback from end-users, whether they are construction workers, farmers, or homeowners, guides practical enhancements to handle durability and usability. Companies often employ teams dedicated to testing and refining these handles under diverse conditions, ensuring that each iteration addresses previous shortcomings while fulfilling emerging demands. In conclusion, the wire bucket handle exemplifies a blend of engineering finesse, practical design, and industry reliability. A critical component across numerous applications, its importance cannot be understated. By focusing on quality construction, ergonomic design, and robust safety standards, manufacturers not only meet but exceed the expectations of a diverse audience. The evolution and meticulous craftsmanship of wire bucket handles highlight an unsung hero essential to countless day-to-day operations.

Next:

Latest news

-

Wire Mesh for Every Need: A Practical SolutionNewsJul.25,2025

-

Steel Fences: Durable, Secure, and Stylish OptionsNewsJul.25,2025

-

Roll Top Fencing: A Smart Solution for Safety and SecurityNewsJul.25,2025

-

Cattle Farm Fencing Solutions for Maximum SecurityNewsJul.25,2025

-

Affordable Iron Binding Wire SolutionsNewsJul.25,2025

-

Affordable Galvanized Wire SolutionsNewsJul.25,2025

-

Wire Hanger Recycling IdeasNewsJul.25,2025

Related PRODUCTS