-

Phone:

Phone: -

Email:

Email:

Rockfall Netting Suppliers High-Strength & Affordable Slope Protection

This comprehensive guide explores critical aspects of rockfall protection systems. Below is the structured outline:

- Fundamental Role of Rockfall Protection Systems

- Material Engineering and Performance Metrics

- Technical Specifications Comparison

- Supplier Evaluation Framework

- Project-Specific Engineering Solutions

- Industry Implementation Scenarios

- Procurement Strategy Considerations

(rockfall netting suppliers)

The Critical Role of Rockfall Netting Suppliers in Infrastructure Safety

Specialized barrier systems prevent geological hazards along transportation corridors. High-tensile steel wire mesh installations intercept debris before reaching vulnerable zones. According to Alpine Infrastructure Journal, properly installed systems reduce maintenance costs by 63% annually versus reactive cleanup methods. Industry-leading suppliers maintain ISO 9001 certification while delivering systems rated for up to 5,000 kJ impact resistance.

Material Engineering and Performance Metrics

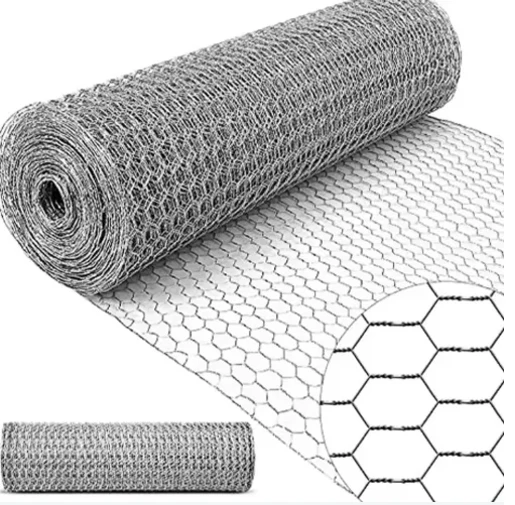

Galvanized steel alloys with optional PVC coating resist corrosion for 20+ years in harsh environments. Double-twisted hexagonal mesh patterns provide flexibility while maintaining structural integrity under dynamic loading. Third-party verification confirms energy absorption capacities between 1,000-8,000 kilojoules, with deflection characteristics optimized through computational modeling. UV-stabilized polymer coatings maintain material properties beyond 15 years of sun exposure.

Technical Specifications Comparison

| Specification | Standard Grade | High-Performance | Ultra-Duty |

|---|---|---|---|

| Mesh Size | 8x10 cm | 6x8 cm | 5x7 cm |

| Wire Diameter | 2.7 mm | 3.0 mm | 3.4 mm |

| Impact Rating (kJ) | 3,000 | 5,000 | 8,000 |

| Corrosion Protection | Class A Galv | Class A Galv + PVC | Galfan Alloy |

Supplier Evaluation Framework

Top manufacturers demonstrate specific capabilities through documented project histories and testing protocols. Essential considerations include independent EN 10223 certification, in-house prototyping facilities, and geographic-specific loading calculations. Market analysis reveals production lead times ranging from 3-12 weeks depending on engineering complexity. European suppliers typically maintain larger stock inventories but face longer international shipping durations versus regional producers.

Project-Specific Engineering Solutions

Customized installations accommodate unique geological conditions through parametric modeling. Variable mesh densities address specific energy absorption requirements, while specialized anchor patterns compensate for complex surface irregularities. Post-tensioning systems maintain optimal contact pressure across irregular slopes. The Norwegian E6 Highway project utilized zoned reinforcement strategies reducing material costs by 28% through targeted engineering.

Industry Implementation Scenarios

Mining operations demonstrate the most rigorous durability standards with 10mm double-layer configurations intercepting 15-tonne boulders. Transportation authorities increasingly deploy TECCO® systems along mountainous routes where slope access restrictions necessitate helicopter installation. The Canadian TransMountain expansion incorporated 7.2km of hybrid cable netting that withstood 6.2 magnitude seismic activity during deployment.

Making an Informed Decision on Rockfall Netting Purchases

Procurement professionals prioritize lifecycle value over initial expenditure when evaluating solutions. Technical specifications should drive selection criteria rather than rockfall netting price alone. Reputable suppliers provide documented installation protocols and maintenance schedules critical for warranty validation. Industry surveys indicate 92% of engineers prioritize manufacturers offering site-specific certification packages and geotechnical consultation.

(rockfall netting suppliers)

FAQS on rockfall netting suppliers

Q: How do I choose reliable rockfall netting suppliers?

A: Prioritize suppliers with ISO certifications, proven industry experience, and client testimonials. Verify their compliance with ASTM or EN standards for rockfall protection systems.

Q: What factors influence rockfall netting price?

A: Pricing depends on material type (steel wire vs polymer), mesh density, coating treatments, and project scale. Custom designs and remote installation sites may increase costs.

Q: What types of rockfall netting are available?

A: Suppliers typically offer double-twisted hexagonal mesh, high-tensile steel wire mesh, and ring net systems. Options vary in energy absorption capacity from 500-5,000 kJ.

Q: Do suppliers provide rockfall netting installation services?

A: Many suppliers offer turnkey solutions including engineering design and certified installation crews. Some collaborate with specialized geotechnical contractors for complex projects.

Q: What warranty do rockfall netting suppliers typically offer?

A: Standard warranties range 10-25 years for galvanized steel systems, with polymer mesh typically having 5-15 year guarantees. Coverage includes material defects and corrosion resistance.

-

Wire Mesh for Every Need: A Practical SolutionNewsJul.25,2025

-

Steel Fences: Durable, Secure, and Stylish OptionsNewsJul.25,2025

-

Roll Top Fencing: A Smart Solution for Safety and SecurityNewsJul.25,2025

-

Cattle Farm Fencing Solutions for Maximum SecurityNewsJul.25,2025

-

Affordable Iron Binding Wire SolutionsNewsJul.25,2025

-

Affordable Galvanized Wire SolutionsNewsJul.25,2025

-

Wire Hanger Recycling IdeasNewsJul.25,2025